GodSpeed – When you go so fast you see God.

I was inspired to learn how to shape surfboards when I was in high school. I hand shaped 13 boards, and glassed 5 of them. I realized that glassing was a skill that I didn’t have, and I really didn’t like the chemicals or dust, so since board # 5 I left the glassing to somebody else. My first teacher was Cole Simler of Cole Surfboards. We both eventually left that town, and neither of us could keep up the correspondence or surfboard relationship, so we drifted apart. Cole is still shaping boards, and has a great quiver available if you’re in Southern California.

Through a chance board-borrow, I ended up a team rider for Shane Stoneman Surfboards for 10 years. If I lived in Shane’s town, I would probably have a garage full of his boards, and somebody would have to give me a yearly budget or I’d blow all my money on his gear.

The story I tell about Shane is that never, in all the boards that he shaped for me, did I once give him any dimensions. There ended up being a few surprises, like when I wrote him asking for a “big wave” version of the last board he had sent me. Like all of the boards that he shapes for me, the board had to travel from California to Indonesia and somehow arrive unscathed on a small island, prepared to be smashed by whatever waves the Indian Ocean could dish up. So with expectations high of some big wave “gun” that I’m going to receive, I pull a 5’7 board out of the bag and am left scratching my head. Either Shane misunderstood, or maybe he’s just trying to kill me? But, having the relationship that we have, I trusted him and took the board out into some rather large surf. One memorable barrel in 2010 at Bankvaults left me with an unresolved curiosity. Did this seemingly tiny board work in large waves because Shane consciously made it that way, or did my belief in his skills somehow propel me into a new level of faith on the drop? Or maybe it was a combination of him and I that believed I had the skills to ride this potato chip in big waves?

Eventually though, the logistics and pre-planning involved in getting a board from California to Indonesia grows old, and I started looking for a way to get boards made locally. On a trip home to NZ I reached out to a friend Tommy Dalton who had recently taken over his father’s shaping business in my hometown. Tommy had earned the license to shape for Mayhem in NZ, and spent a month every year with Matt Biolos, so I knew he could make a good board. Him and I worked remotely to design a mini-mal that I thought would be perfect for NZ summer time and small waves. Sometimes Tommy uses a computer board shaping machine, and this was a new experience for me. The board looked good and worked well, and when I returned to Indonesia, I asked Tommy if he would please send me the file so I could have one made in Bali, using the same file. Tommy sent me the measurements as a pdf, but refused to send me the actual shaping file. I could understand his point of not wanting other shapers to have his rail shapes, his rockers, or whatever else was proprietary about his computer file, but I didn’t agree with him.

Being refused by Tommy lit a fire to learn the AKU board shaping program myself, so that I could shape my own boards, and share the boards and files with whoever was interested in what I was doing.

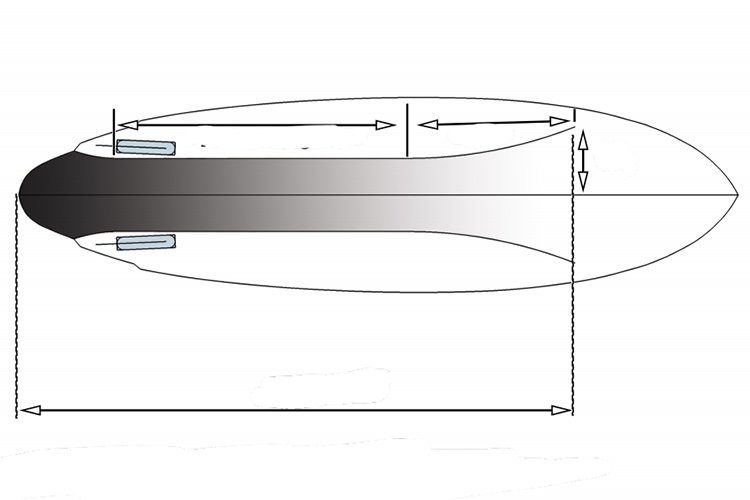

Luke Studer in Bali was the recipient of my AKU shape # 1, an attempt to copy the mini-mal from NZ. Another friend from South Africa used the same program when he attempted a copy of my favorite Stoneman board, and then sent me the file. I modified that file and sent it to Studer to be # 2. I really like the collaboration aspect of this computer board shaping experience, where you can take an idea from somebody else, and build on it. It was like my experience of designing boards, but with instantaneous satisfaction, and without the 5,000 miles transport + 6 months needed to wait for my next new board to turn up. I think our surfing and the ways we approach waves evolves faster than we think, and sometimes the million dollar idea we had last year seems quaint compared to what’s going on now.

Studer got too busy with the expansion of his business, so I started sending the files to Patrick Napoli of Redz Surfboards in Bali. Patrick and I have collaborated on boards #3, 4 and 5. I hand finished board #5 myself in Bali, and Patrick took my modifications to create a duplicate board # 6. Board # 6 finally fulfilled the concept of creating a board for somebody else, but with the added twist that the board design had never been tried before.

Part of the GodSpeed philosophy is pushing the technology boundary. I’m shaping boards on my laptop, and sending the files via internet to Bali, 2,000 miles away. Then a human working with a computer and a machine is essentially 3-D printing my creation, glassing it and sending it to me. Between the laptop’s processor speed allowing me to run the program, the internet which is bouncing between coconut trees on its way to Sumatra, the shaping machine located on a different island, and the tracking and logistics of the board winding it’s way on a truck back to our island, the whole exercise feels cutting edge and there’s always something new to learn and try out.

So if you’re interested in going fast on a surfboard, and want to take a leap of faith with a completely novice shaper, drop me a line and hopefully I can help you go so fast you too can see God. There is some content on my instagram page for GodSpeed, and videos of R&D available in HD on the GodSpeed youtube channel.